- Home

- Equipment

Refine by

Conveyor Dynamics Environmental Equipment & Supplies

5 equipment items found

Manufactured by:Conveyor Dynamics based inSaint Peters, MONTANA (USA)

Furnace charging feeder conveyors are designed to meter melt stock into electric furnaces or Cupola charging buckets. They are usually mounted on a powered indexing carriage that retracts after the load is discharged. These units are designed to hold a specific amount of material (such as 10 tons) which is weighed via load cells. The crane operator views a large digital readout score board with ...

Manufactured by:Conveyor Dynamics based inSaint Peters, MONTANA (USA)

Transfer Conveyors are specialized material conveying units intended to facilitate seamless movement of products between conveyors or machinery, such as a DIDION Rotary Drum. These systems are designed with an incline conveyor mechanism that ensures a smooth transfer by synchronizing speeds between connected conveyors. The downstream conveyor is typically calibrated to operate at a marginally ...

Manufactured by:Conveyor Dynamics based inSaint Peters, MONTANA (USA)

Sorting conveyors are engineered to facilitate the easy separation of components from extraneous materials, such as distinguishing cast parts from gates, runners, and sprues. Typically featuring a gull wing design for maintaining separation, these conveyors can be customized for specific applications. They may include multiple lane troughs, curves, and chutes to enhance sorting efficiency. The ...

Manufactured by:Conveyor Dynamics based inSaint Peters, MONTANA (USA)

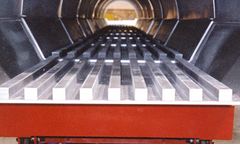

The Casting Accumulator/Cooling Conveyors are engineered to efficiently manage cast production, accommodating up to an hour or more of output and facilitating effective cooling. These systems utilize a clever air flow method where air is directed through a lower plenum and across a bed of castings before being expelled through the top dust hoods. This design allows for the transition and dwell ...

Manufactured by:Conveyor Dynamics based inSaint Peters, MONTANA (USA)

Conveyor Dynamics specializes in the manufacturing of vibratory feeders designed to accommodate a range of material handling needs. These feeders are offered in various sizes from 8 to 20 feet in length and can be customized with different trough designs to suit specific requirements. The design flexibility allows for the inclusion of replaceable wear-resistant liners, dust and fume hoods, ...